PRODUCTS

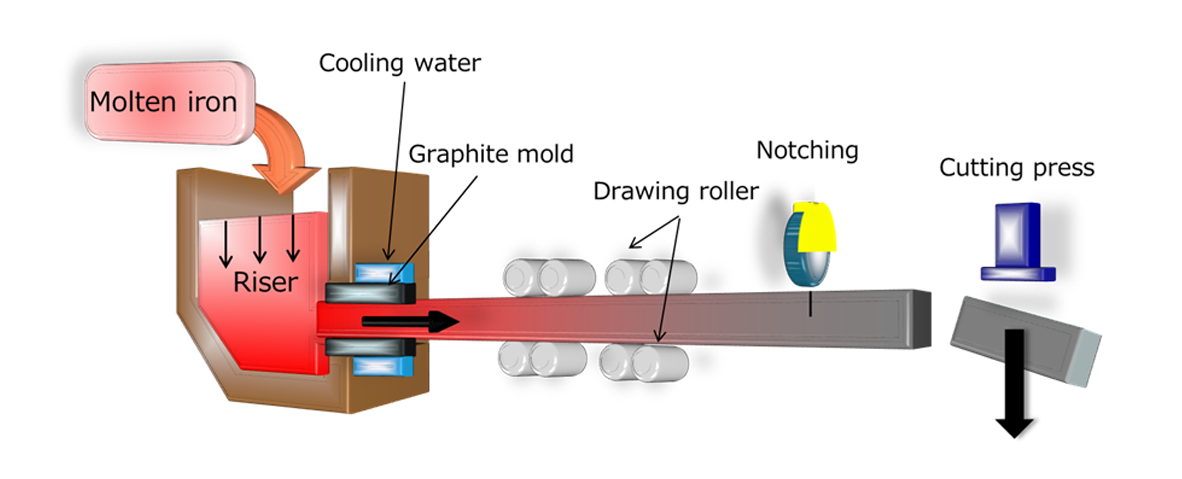

Iron is melted in a electric furnace with quality and temperature controlled. Then the molten iron is water-cooled on the surface, and flows into a properly shaped graphite die where its surface is cooled rapidly to form a solid shell.

When the product is drawn by drawing rollers, a quantity of new molten iron equal to the drawn amount flows into the mold, thus repeating the sequence of cooling-solidification-drawing continuously.

When drawn out of the graphite mold, the solid layer of the iron surface is reheated by the core section which is still in the melted condition. So the iron is kept from becoming white iron by this self annealing effect.