取締役および執行役員の異動ならびに人事異動に関するお知らせを掲載しました。

こんなところに虹技

街のなかにある虹技の製品をマップでご紹介。

ご覧になりたい箇所をクリックしてください。

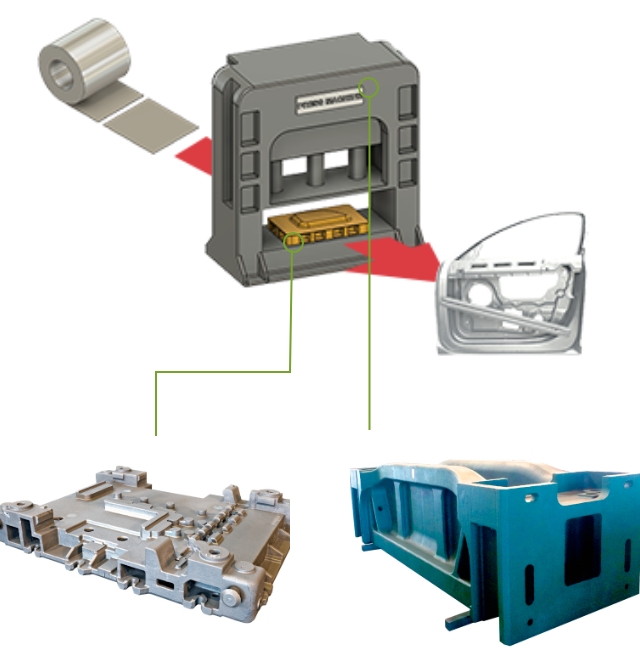

自動車

ボディ外板

自動車のボディ外板を加工する「プレス機械」、

「金型」には当社の鋳物が使われています。

プレス加工は自動車を始めとする製造業では欠かせない加工方法です。

虹技では「プレス機械」を構成する部品において、最大重量40tの鋳物製品を製造・供給しています。

「自動車ボディプレス金型用鋳物」は、自動車ボディの材料となるパネルをプレス成型するための金型です。

ドア・バンパー・サイドパネルなど、あらゆるボディパネルのプレス金型を通じて、自動車産業を支えています。

ブレーキ

ブレーキパッド(摩擦材)の原料に

当社のKCメタルファイバーが使われています。

“KCメタルファイバー“は、びびり振動切削法によって作られた金属短繊維です。

自動車をはじめ、二輪車や産業用摩擦材の原料として使用されており、安全なクルマ社会に貢献しています。

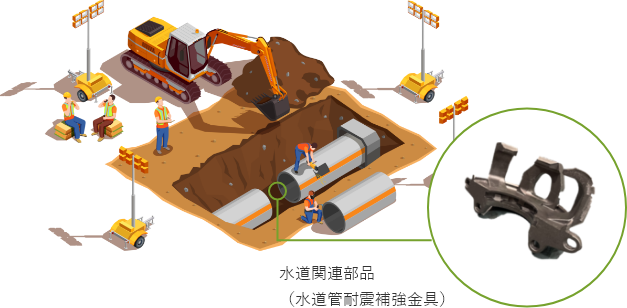

道路

マンホール鉄蓋・公共関連鋳物

道路上に設置されるマンホール鉄蓋やグレーチングなどに使われています。

(姫路市)

(京都市先斗町)

下水道や上水道、無電柱化など災害に強い街づくりに貢献するライフライン整備に携わる鋳物製品を中心に製造しております。

建設現場

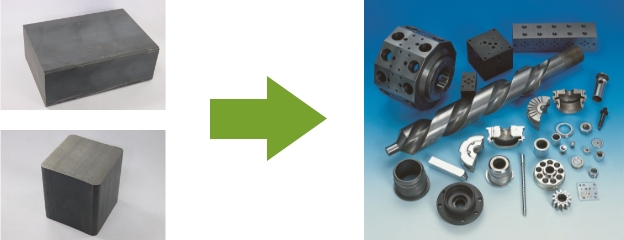

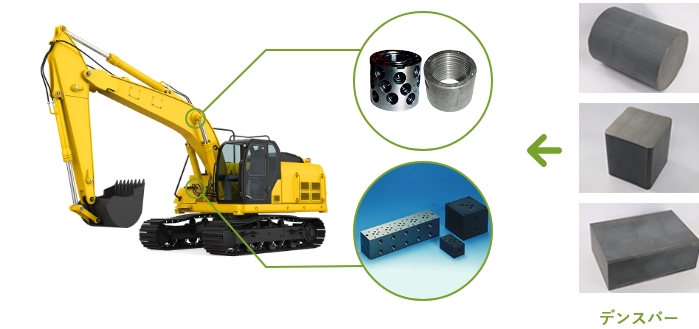

建設機械

建設機械の駆動部の要:油圧に関わる部品には

“デンスバー“を加工して使われています。

ショベルカーやホイルローダー等の建設機械、そのパワーの源となる『油圧』。

デンスバーはマニホールドブロックや各種バルブ、ピストン等の油圧部品の素材として皆様の近くに存在しています。

建築資材

建築構造用鋼材を製造する工場の圧延工程では、

当社の圧延ロールが使用されています。

H形鋼・山形鋼・溝形鋼・異形棒鋼等、様々な建築用鋼材を圧延する際に、当社の圧延ロールが使用されています。

H形鋼向けにおいては小形用~大形用まで幅広いサイズに対応したロールの製造・販売をしています。

工場(機械工場)

産業機械

産業機械の様々な部分で当社の産業機械鋳物・

機械部品に使われています。

冷却機器

圧縮空気を用いて、風量の増幅・冷風を生成する機器を取り扱っています。

エアーブロー・排気・吸引・加工機の刃先冷却などに使用され、省エネや設備の保全に貢献しています。

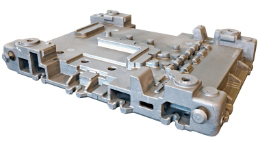

工作機械用鋳物

虹技では旋盤、門形加工機、プレス機など各種工作機械向けに、テーブル、ベッド、フレームなど様々な鋳物部品を製造・供給し、産業設備を支えています。

プラント

ごみ焼却炉

各家庭で排出される一般ごみを焼却処分する設備です。

当社では都市ごみ焼却炉の設計・施工管理を行っており、環境に配慮した焼却設備の開発に取り組んでいます。

冷却機器 “ボルテックスクーラー“

圧縮空気を利用した機器で各工場・プラントにおいて使用されます。

圧縮空気を動力とし、フロンを使用しないため、環境にやさしい冷却機器です。

主に、制御盤内の冷却や・監視カメラの内部を冷やす用途に使用され、設備の保全に貢献しています。

送風機

空気に圧力を与え風を送り出す機械です。

集塵装置・燃焼装置等の様々な設備に利用されています。

当社では送風機の設計・製作を一貫して行っており、お客様のニーズに合わせた、オーダーメイドの送風機を製作しております。

工場(製鉄所)

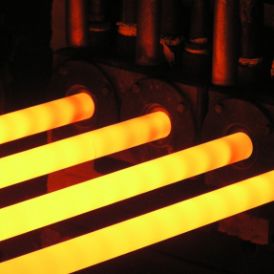

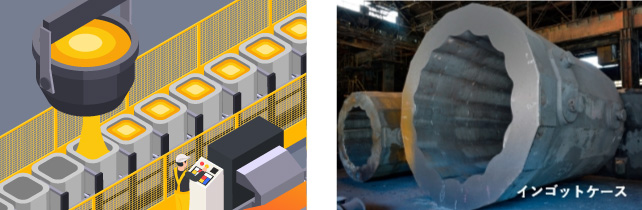

鋳造工場

特殊なサイズ・材質の鋼塊を作るために、

インゴットケースが使われています。

「インゴットケース」とは溶かした金属を流し込み、【鋼塊=インゴット】とよばれる金属素材をつくるためのケースです。

創業当初よりインゴットケースで培った技術を基に、各種様々な耐熱鋳物の設計~製作まで行っております。

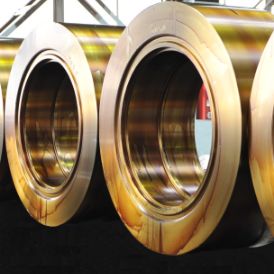

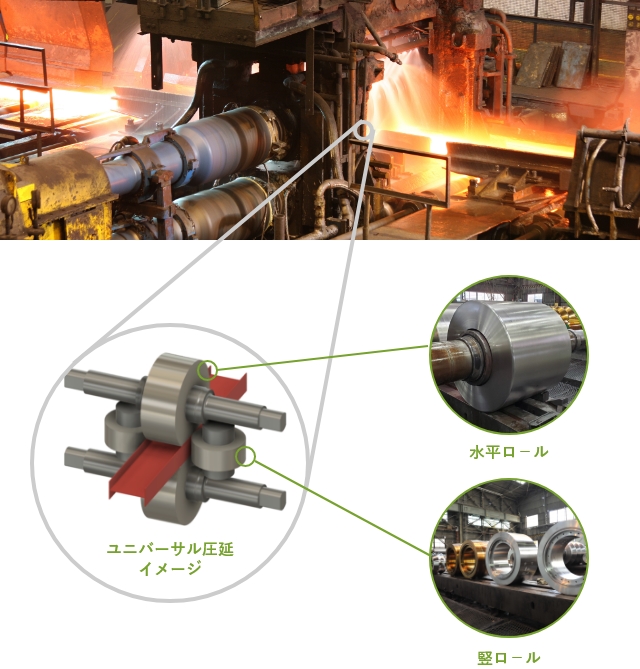

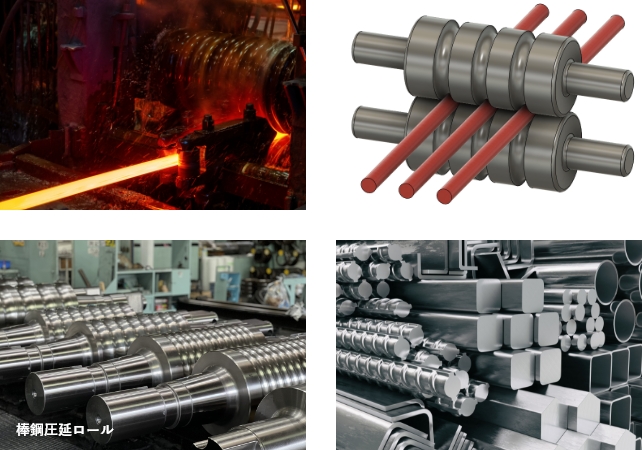

圧延工場

鋼片を様々な形状に加工する圧延工程では、

当社の圧延ロールが使われています。

線材・棒鋼・形鋼・鋼板・パイプ等、様々な材質・形状の鋼材を製造する上で「圧延ロール」は欠かせない部品の一つとして、鉄鋼産業を支えています。

分塊~仕上・矯正用ロールまで用途に応じた材質を取り揃えています。

※レイアウトが崩れる場合、ブラウザを縮小してご覧ください。

BUSINESS 事業紹介

虹技株式会社 -KOGI C&E GROUP- 会社案内映像